Investigating surface coating effects on the ice adhesion behavior of woodchips

New publication in Novias series R: Investigating surface coating effects on the ice adhesion behavior of woodchips, A Nordic Icing Centre of Expertise report.

Abstract

This project investigates the effect of surface coating on ice adhesion of frozen woodchips. The study was initiated by challenges faced by forestry workers in winter, specifically the storage and transportation of woodchips from the forest to the plant.

The first part of the report presents a review of such available methods of anti-icing and de-icing as chemical spray, container lining, thermal coating, industrial vibrators and heating system.

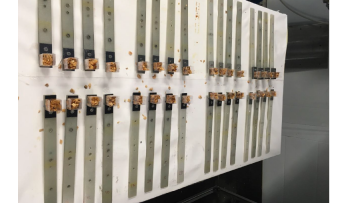

The second part of the report deals with experimentation. This part is divided into two different testing protocols at -10°C. In the first protocol, 5 boxes are made with different coatings to evaluate the detachment time from the shear of the bottom plate at room temperature. The coatings include FS-SLIPS, PE Quicksilver lining, FS-PE rough, FS-PE smooth, steel covered with rapeseed oil and steel with sprayed silicone oil. In the second protocol, 9 surfaces are investigated with centrifuge ice adhesion tests (CAT) at -10°C, where the coatings include the same materials as the boxes as well as uncoated steel and steel covered with antifreeze and PTFE tape.

Both protocols result in similar trends regarding the FS-SLIPS + silicone oil. It has fast ice removal and low ice adhesion which make it the most promising results.

This report gives a comprehensive overview of the existing methods on ice-adhesion. Every solution tested gives a lower ice-adhesion than stainless steel.

Picture: Figure 15. Final samples composition woodchips and ice mixture. 4 samples x 8 testing surfaces.