The Impact of Technological Advancements on Supply Chain Management

A Case Study of the Garments Industry in Gazipur, Bangladesh

Did you know that Gazipur, a booming district in Bangladesh, plays a great role in the ready-made garments (RMG) industry globally? The truth is that being in a competitive market and holding the same position in today’s fast-paced world is not easy, especially when managing different levels of complex supply changes.

Fortunately, technology is stepping in as a game-changer. From making processes faster to improving transparency, technological advancements are reshaping the way Gazipur’s factories operate. Let’s explore how technological advancements are making effective supply chain management (SCM) in this vital region.

Introduction to Supply Chain Management in the Garments Industry

Overview of Supply Chain Management

Supply chain management is crucial to any industry, especially in the garments sector. It includes the coordination of complex management and the network of production of raw materials into finished products. SCM's prominence is found in its ability to enhance working efficiency, decrease costs, and improve customer satisfaction. The main parts of SCM in the garments industry include sourcing different materials, production planning, inventory management, and logistics. Existing companies can react effectively, align with market demands, and maintain a competitive threshold.

The Garments Industry in Gazipur

Gazipur is located just beside Dhaka city, Dhaka is the capital city of Bangladesh and Gazipur is the biggest garments zone situated just beside Dhaka in Bangladesh, this zone is named as a garments zone or hub in the garments industry. The region plays a critical role in the overall country’s economic improvement and acts as a main sector to earn foreign currency and arrange extensive employment for the country where millions of workers are working and earning their livelihood. Besides this industry encounters many challenges, for example, labor costs are rising day by day, coping with international compliance with international standards, and fewer uses of technology like automation, robotics, and advanced data analyzing processes. These challenges are very crucial for the sector.

The Old Way vs. The New Way

Imagine how conventional garments were made in the old days, all kinds of materials reached the factories, and accessories arrived, due to the lack of communication a lot of delays happened. Factories workers manually did inventory, possibly leading to errors.

And manufacturing of orders took longer than the estimated timeline. Do you think this is familiar to you?

Now Imagine this:

- All the accessories and materials arrived at the factory according to the plan

- Actual update time tracking and get to know where exactly the shipment is.

- Automatically systems reduce errors and save time and efficiently the work process.

- And that’s the magic of grasping new technology into the supply chain management (SCM)

Old Factories image:

Advanced Factories Image:

Here's a visual comparison of the garment industry in Gazipur, Dhaka, Bangladesh, showcasing the transition from traditional, manual operations to a modern, technology-driven factory setting

Meet the Heroes of this Tech Revolution

Some smart and cool technologies are behind these modern changes. IoT (Internet of Things): Think of tiny measuring devices like sensors that easily tell you where the factory’s fabric shipment is currently located and even halfway across the world.

AI (Artificial Intelligence): This is a smart system in a picturized way, and it demands and adjusts production schedules accordingly.

ERP (Enterprise resource systems): Here you can see everyone on the same page- from suppliers to managers. ERP is a one-stop software solution that makes your supply-chain management at a glance.

Stories from Gazipur's Factory Floors

Now let us consider a quick look into the lives of the people leading these changes.

Meet Kolpona, a production manager in Gazipur, she took hours to coordinate shipments and very often encountered delays because of not having a proper modern system. After having a lot of delays, and fewer orders, her factory adopted an IoT-enabled tracking system. So now she is thrilled and says, “I can track all of my material and accessories shipment and it's like every information is in my hand’’

Or Ashraf, a floor worker, was initially very fearful about using automated machines. But after getting proper training, he realized that the technology didn’t replace his job, it makes it efficient. He says, “Now I focus on different roles as quality control, and I just love it.’’

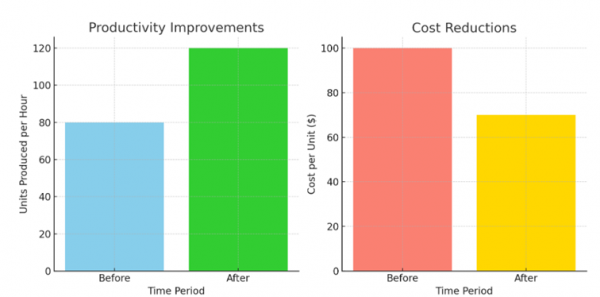

Here after using the new technology and using new technology productivity improvements and costs also reduce.

What’s in it for Everyone?

The technological revolution isn’t just about the speediness and efficiency of only supply chain. They are transforming the acts of everyone’s life.

- For Factories: Faster processes, fewer errors, lower costs, on-time shipment.

- For Workers: Better tools to make their jobs productive efficient, easier and safer.

- For the Planet: Sustainable practices, like energy-efficient machines, are reducing environmental impact.

The Bumps on the Road

- Surely, sailing is not all easy. Small businesses in Gazipur may face confronts like this

- High cost of installing new advanced technology.

- Shortage of skilled workers

- Resistance to adopting a new system

- But here’s the good news: training programs and government incentives are starting to bridge these gaps.

Why This Matters to You

There is something to learn here even if you are not an employer in the apparel sector. The voyage of Gazipur helps as a reminder that even the most difficult problems can be competently solved through creativity and adaptation.

Do you work in a sector that is having trouble with obsolete systems? Start small and draw inspiration from these factories. Every step matter, whether it's automating tedious chores or digitizing inventory.

What’s Next for Gazipur’s RMG Sector?

The future looks bright! Factories are steadily adopting cutting-edge technologies like blockchain for better transparency and robotics for precision manufacturing. With the right support, Gazipur could become a global leader in sustainable, tech-driven garment production.

Join the Conversation

What do you think about the role of technology in supply chains? Have you seen similar transformations in your industry? Or do you have ideas for overcoming the challenges Gazipur’s factories face?

Let us know in the comments below, and don’t forget to share this blog if you find it insightful!

Short Biography of Author:

Mukta is pursuing an MBA in Digital Business and Management at Novia University of Applied Science, Vaasa. She was a Senior Merchandiser with H&M group (H&M is a Swedish apparel brand) and experienced diversified product knowledge and operations. Her academic focus on digital business counterparts and her practical background help to make her well-equipped to manage both the traditional and digital aspects of business management.

In this blog you'll read posts from students studying for Master of Business Administration, Digital Business and Management, MBA. The writers are responsible for the content and opinions in the blog text.

Digital Business and Management, MBA

Disclaimer: The author(s) are responsible for the facts, any possible omissions, and the accuracy of the content in the blog.The texts have undergone a review, however, the opinions expressed are those of the author and do not necessarily reflect the views of Novia University of Applied Sciences.

Posta din kommentar

Kommentarer

Inga har kommenterat på denna sida ännu